Now Available: Threaded Inserts for Plastic

About RAF Electric Hardware

RAF Electronic Hardware is the nation’s leading supplier of electronic hardware, threaded inserts for plastic, and high-volume screw machine products. Since 1975, RAF has offered a wide range of products in both American standard and metric dimensions for immediate delivery. RAF has also combined with Tri-Star Industries and now offers an extensive product line of threaded inserts for all types of plastic applications and can provide assistance with technical, application, and installation questions, as well as custom designs and insert testing.

Most electronic hardware catalog items are off-the-shelf and available for same-day shipment. RAF can also supply any customized products with small minimum orders and competitive pricing.

To learn more about our precision machining department and quick turn abilities, View Our Machining Capabilities.

Compliance

Certifications & Quality Documents

All Documents

Find all our documents, including certifications, statements and policies, material safety data sheets, and more.

Industries We Serve

Our Manufacturing Services

-

RAF Electronic Hardware offers prototypes or sample parts for a variety of custom components including screws, fasteners, threaded inserts, and other precision metal parts. We also offer rapid prototyping for select components, with shipping in as little as one to two weeks.

-

CNC machining is a manufacturing process where computer software is used to control complex tools or machinery without the need for manual operations. Some examples of CNC machining services we offer include milling, turning, micromachining, metal stamping and forming (including fourslide technology), and wire forming and wire rolling.

-

Milling

MillingMilling is accomplished using computerized controls to operate motorized cutting tools.

-

Turning

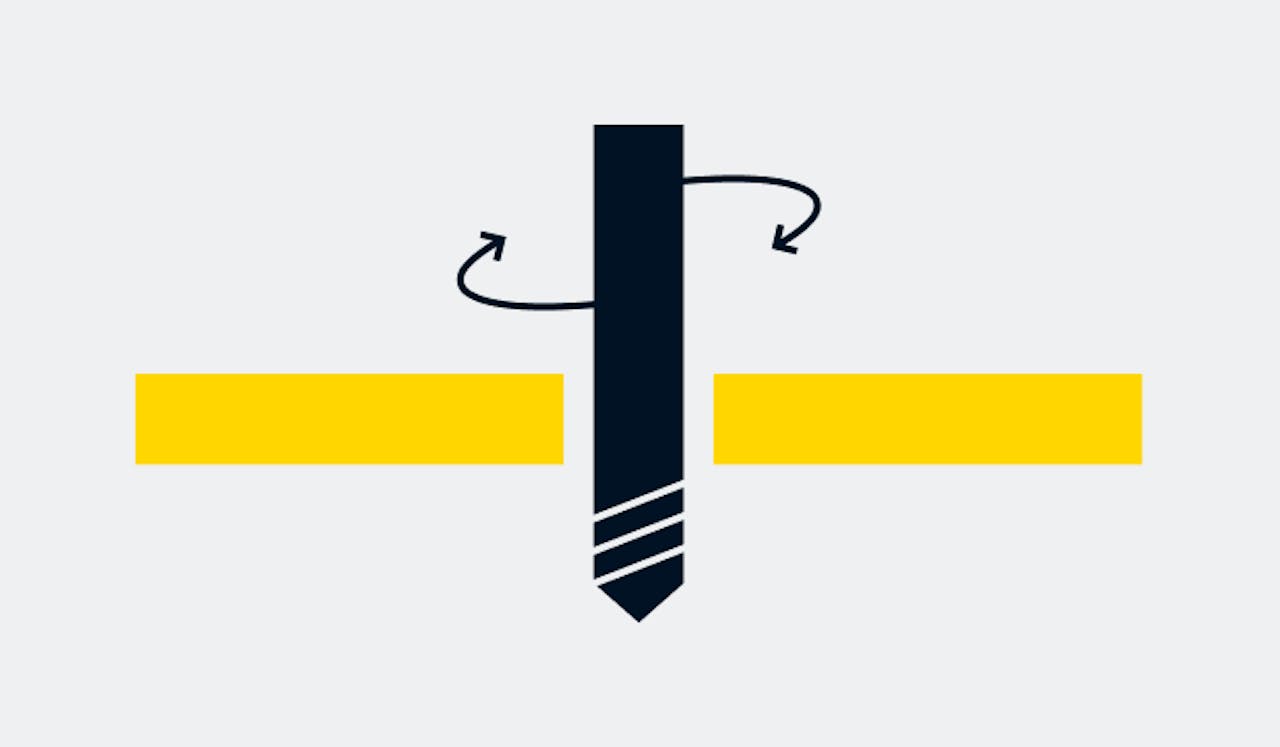

TurningThe manufacturing process known as CNC turning involves feeding metal bars into a machine and applying one or several tools that gradually shape the material into the desired form. Examples of capabilities that our precision turning centers have include Swiss lathe machining, threading, tapping, cross drilling, end or side milling, and broaching.

-

Drilling

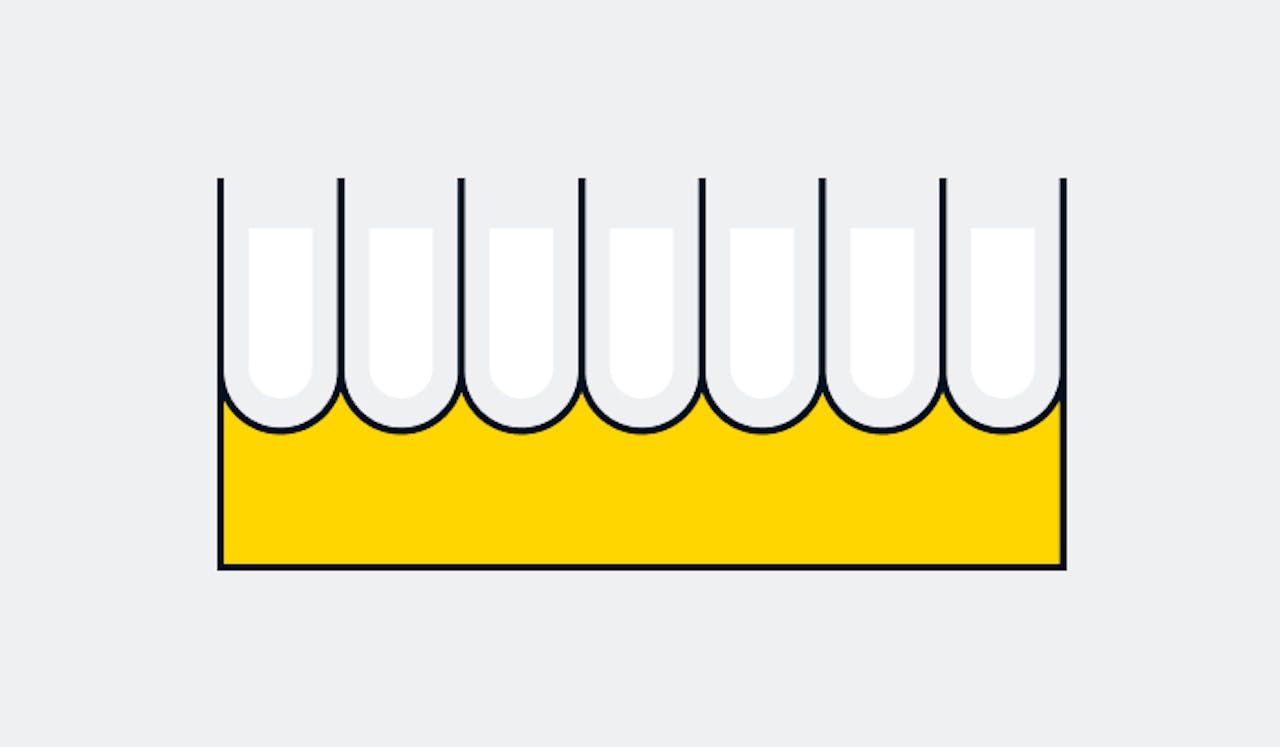

DrillingDrilling is the process of cutting one or several holes into a material using a machine equipped with a drill bit.

-

We perform precision sharpening and CNC grinding services including electrochemical grinding in the production or finishing phase as needed for your intended application.

-

Anodizing

AnodizingThis is a passivation process used to thicken the natural oxide layer on the external surface of metal components. This offers added protection for aluminum alloys, titanium, zinc, and other metals.

-

Coating is used most often to resist environmental factors like corrosion or embrittlement.

-

Outside of hardening and tempering, we offer a variety of other heat treatment options to ensure your desired ranges are reached for cycle-life, toughness, and resistance to environmental forces.

-

Plating

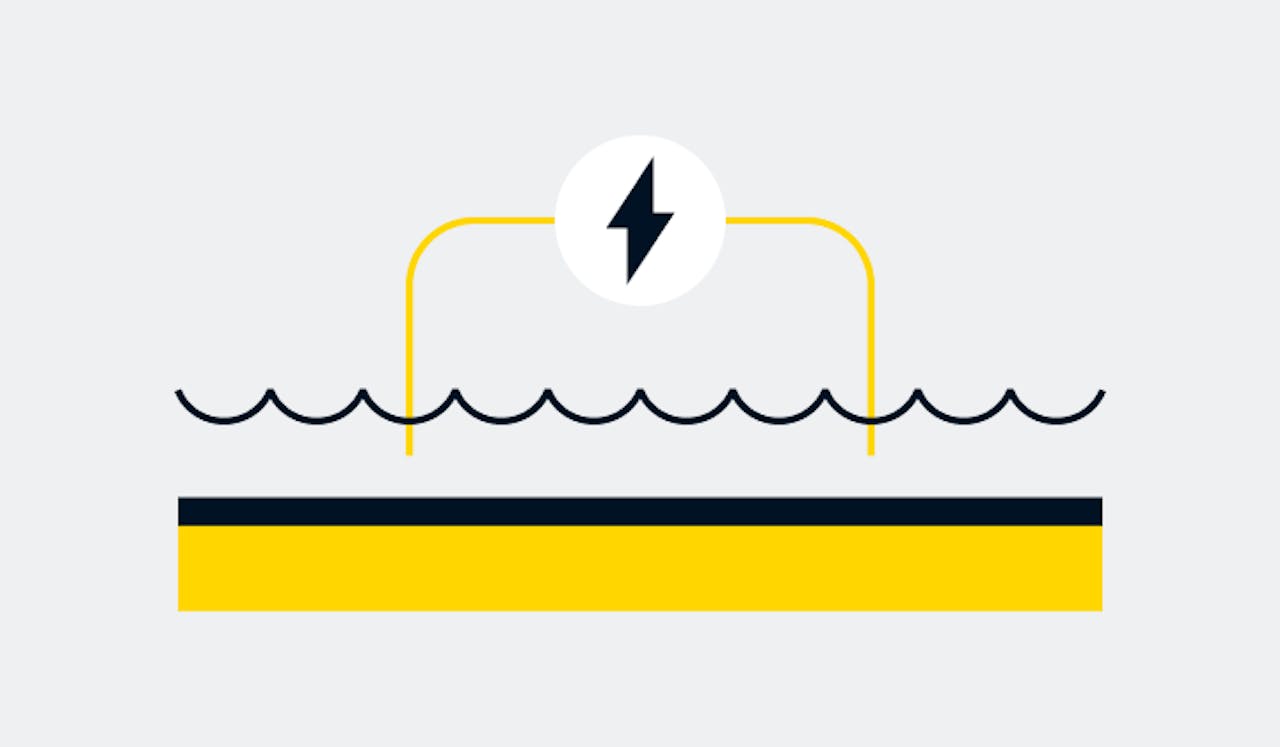

PlatingPlating is a manufacturing process where a thin coating is applied to a component’s surface through chemicals or electric current (electroplating).

-

Hardening & Tempering

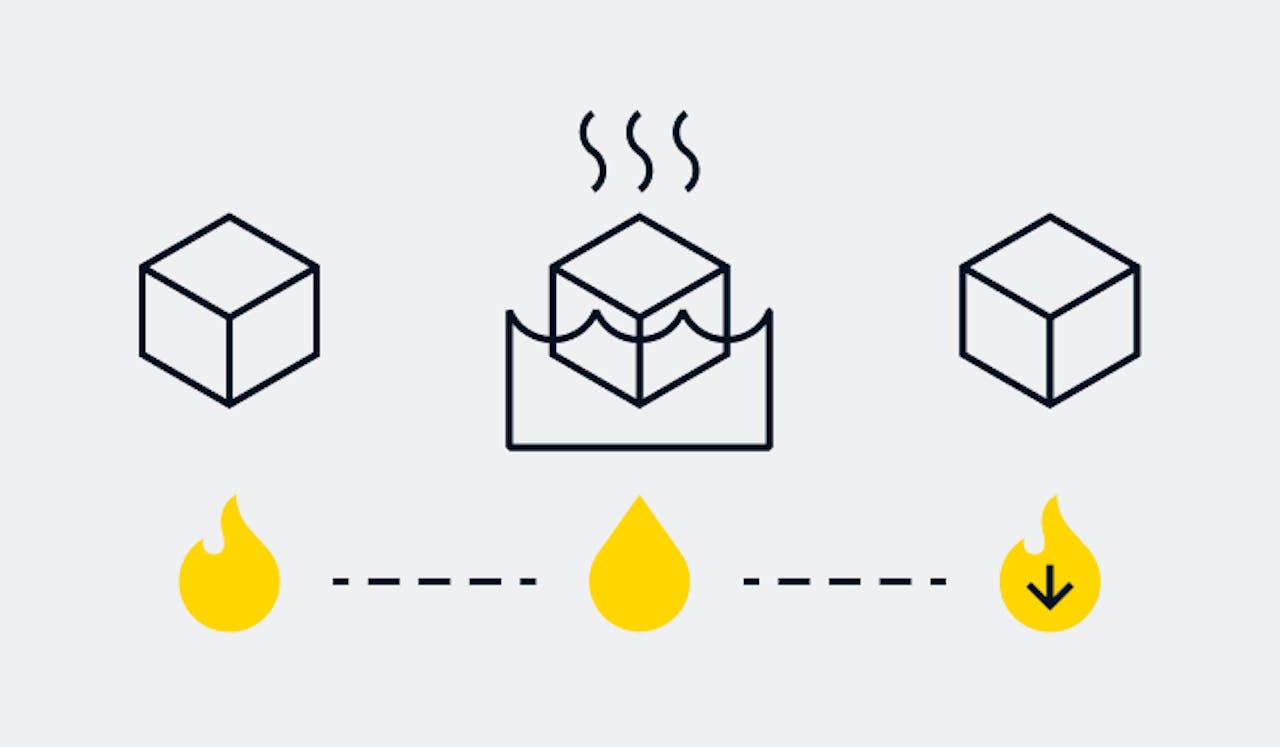

Hardening & TemperingHardening and tempering produce required hardness ratios in metals like steel or stainless steel to ensure desired performance. Harding, as well as case hardening, and straight hardening, involves heating the metal and then cooling it to transform its standard properties, while tempering is a process of applying low-temperature heat treatments, generally after a hardening process has been completed.

-

Would you like to make your overall production process more efficient? We offer part assembly services with both new and existing components. Ship your coordinating parts to us, and we’ll put them together to the requirements and timeline you specify.

-

Do you need specialized packaging? We work with your teams to determine the best way to build and package your products to ensure efficient assembly with your existing components.

-

Production or machine tooling is the development of a specialized production process for a new part or product.

-

Optimize your designs to reduce cost, improve performance, and accelerate time to market.

-

RAF provides quick turn service or Just-In-Time (JIT) delivery to ensure that you get the products you need when and where you need them. From rapid prototyping to next-day shipping on in-stock items, we deliver with speed and efficiency.